Plastic Market Surges Toward USD 1,138.2 Billion by 2035, Driven by APAC, Europe, USA, and KSA Manufacturing Expansion

Polyethylene (PE) will dominate with a 27.0% market share, while injection molding will lead the processing technology segment with a 36.0% share.

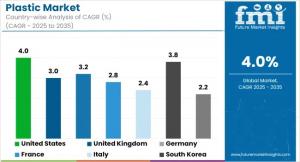

OSAKA CITY, OSAKA PREFECTURE, JAPAN, November 7, 2025 /EINPresswire.com/ -- The global plastic market is entering a transformative decade, projected to grow from USD 768.9 billion in 2025 to USD 1,138.2 billion by 2035, registering a 4.0% CAGR, according to the latest industry outlook. Asia-Pacific, Europe, the United States, and Saudi Arabia are emerging as pivotal growth centers as polymer innovation, circular economy frameworks, and advanced manufacturing technologies converge.

Strong Global Momentum

Between 2025 and 2035, the global plastic market is forecast to record an absolute value gain of USD 370 billion, representing nearly 1.5× expansion over the decade.

From 2025 to 2030, market size will climb to USD 936.8 billion, while the following five years will add another USD 202.1 billion, powered by circular economy investments and advanced recycling infrastructure deployment.

Asia-Pacific Leads with Manufacturing Expansion and Circular Growth

China remains the global anchor with 4.9% CAGR, underpinned by integrated refinery-to-polymer operations and surging demand for e-commerce packaging and automotive components.

India emerges as the region’s fastest-growing market at 5.3% CAGR, supported by “Make in India” initiatives, packaging modernization, and formal Extended Producer Responsibility (EPR) frameworks mandating up to 60–70% recycling targets by 2029.

Industrial hubs such as Tamil Nadu, Gujarat, Maharashtra, and Karnataka are driving polymer adoption across packaging, construction, and mobility sectors.

Review the full report to examine in-depth market dynamics, strategic developments, and growth opportunities across key regions! Request Sample Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-15157

Across Japan and South Korea, precision manufacturing and polymer innovation remain central to competitiveness. Japan’s advanced polyethylene and polypropylene systems deliver 98–99% dimensional consistency, while South Korea’s integration of polymer technology into electronics manufacturing reinforces its global supply chain relevance.

Europe Focuses on Circular Economy and High-Performance Polymers

The European plastic market is projected to rise from USD 176.8 billion in 2025 to USD 263.9 billion by 2035, also expanding at 4.0% CAGR.

Germany, France, the UK, Italy, and Spain collectively lead European polymer consumption, with Germany maintaining an 18% market share through advanced chemical engineering capabilities and circular manufacturing integration.

European manufacturers are implementing mandatory recycled content targets (starting at 30% for rigid packaging in 2025 and rising to 60% by 2029), spurring rapid technology adoption in mechanical and chemical recycling. Germany and the UK are front-runners in advanced recycling deployment, while France and Italy are investing heavily in sustainable polymer R&D.

The UK’s plastic packaging tax continues to drive structural demand for post-consumer recycled content and polymer traceability systems.

United States Drives Innovation Through Advanced Recycling and Automotive Electrification

The U.S. plastic market, expanding at 3.8% CAGR, remains the global hub for polymer technology innovation and circular materials integration.

Leading producers — including ExxonMobil, Dow, and LyondellBasell — are investing in chemical recycling facilities across Texas, Louisiana, and Ohio, capable of processing mixed plastic waste streams at scale.

U.S. automotive manufacturers are achieving 25–35% weight reduction in vehicle components through polymer substitution, aligning with federal fuel-efficiency and electrification goals.

Packaging converters across the Midwest and East Coast are upgrading to high-barrier, recyclable polymer systems, while consumer goods manufacturers adopt bio-based and recycled resins to meet brand sustainability commitments.

Saudi Arabia Strengthens Its Petrochemical Leadership

In the Middle East, Saudi Arabia continues to consolidate its position as a global petrochemical powerhouse.

Through major initiatives led by SABIC and Saudi Aramco, the Kingdom is expanding downstream polymer capacity, emphasizing advanced polyolefins, engineering resins, and circular feedstock integration.

The region’s investments in chemical recycling infrastructure and low-carbon production technologies align with Vision 2030 objectives to diversify industrial output and reduce dependence on crude oil exports.

Saudi Arabia’s polymer production ecosystem increasingly supports Asia and Europe’s material demand, reinforcing its strategic role in global supply resilience.

Segmental Landscape: Packaging Dominates, Automotive Gains Momentum

By end-use, packaging applications capture roughly 41% of market share in 2025, with robust growth in food protection, e-commerce logistics, and pharmaceutical packaging.

Automotive applications follow, driven by lightweighting imperatives and electric-vehicle expansion, while construction, electronics, and healthcare collectively reinforce baseline polymer demand.

Processing Technologies Snapshot:

- Injection Molding (36% share) — Dominant due to automation and precision component manufacturing.

- Extrusion — Strong in film and pipe production for packaging and infrastructure.

- Blow Molding & Thermoforming — Core to container and disposable packaging production.

By Product Type:

- Polyethylene (27%) leads globally — with LDPE/LLDPE at 14%, HDPE at 10%, and metallocene LLDPE at 3%.

- Polypropylene, PVC, PET, and engineering polymers contribute substantially across automotive and electronics sectors.

Acquire the complete report to access detailed projections, country-level insights, company share assessments, and technology outlooks! Buy Full Report: https://www.futuremarketinsights.com/checkout/15157

Sustainability and Technology Drive Competitive Advantage

Major producers are aligning portfolios with sustainability and circularity objectives:

- ExxonMobil, Dow, and SABIC are scaling advanced recycling operations and bio-based resin portfolios.

- BASF, INEOS, and LyondellBasell focus on chemical recycling integration and low-carbon manufacturing.

- Reliance Industries and Sinopec expand regional capacity to meet Asia’s packaging and construction demand.

Innovation priorities include:

- Advanced catalysts and polymerization control for custom material properties

- Energy-efficient molding equipment with real-time quality monitoring

- Recycled content certification systems enhancing traceability

- Bio-based polymer development, growing at 5–10% annually, supported by EU and U.S. R&D programs

Industry Perspective

“The next decade will redefine how plastics are produced, used, and recycled,” said a senior FMI analyst at the report launch. “From India’s EPR frameworks to Saudi Arabia’s downstream transformation, every region is aligning its polymer strategy with sustainability and advanced manufacturing goals.”

Exploring Insights Across Emerging Global Markets:

Calcite Market: https://www.futuremarketinsights.com/reports/calcite-market

Controlled and Slow Release Fertilizers Market: https://www.futuremarketinsights.com/reports/controlled-and-slow-release-fertilizer-market

Furfuryl Alcohol Market: https://www.futuremarketinsights.com/reports/furfuryl-alcohol-market

Hexylene Glycol Market: https://www.futuremarketinsights.com/reports/hexylene-glycol-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why Choose FMI: Empowering Decisions that Drive Real-World Outcomes: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.